“Few industries have prospered so rapidly as alluvial gold dredging; whilst twenty-odd years ago there were only a few rudimentary attempts, it is now a prosperous industry contributing each day to global gold production” A. Bordeaux, 1908.

“Dredging is certainly one of the most serious and most interesting industrial experiments to have been carried out in French Guiana” G. Hesse, 1909.

At the dawn of the twentieth century and fifty years after gold was first discovered in French Guiana, the great alluvial deposits in the basins of the Sinnamary, the Mana, and the Comté, often mined by companies from mainland France, were beginning to show signs of depletion. The ease with which gold could be produced during the early years of mining appeared to be a thing of the past.

Each mining company had deposits they were unable to reach lying there before their very eyes – the alluvia lying beneath the riverbeds and marshy alluvial plains that the miners had to abandon during the rainy season. The placer mining technology of the time was unable to resolve these problems. There was also the problem of how to optimise yields. It was against the backdrop of this set of problems facing miners everywhere around the world that a technological shift occurred in goldmining based on techniques derived from port regions. It was a matter of adapting dredging machines, previously used for dredging channels, to be able to use them in the mining of alluvial deposits. This innovation was first applied to the mining industry in California in the 1870s, and then developed rapidly worldwide. In South America alluvial gold dredging developed primarily in French Guiana, and to a lesser extent in Surinam and Guyana.

A gold dredge is a floating factory composed of a hull (or pontoon) made up of an assembly of watertight metallic cases, normally with a steam engine on top fed by a wood-burning boiler, making it possible via a complex transmission system of gears and cables to operate the various moving bits of the machinery: the bucket line used to dig the alluvia and lift the ore up to the dredge, the various winches for manoeuvring the dredge itself (which was manoeuvred using cables anchored to the banks of the river), along with the mechanisms to wash the ore and pump water.

The technical prowess consists in separating the gold from the clay, sand, and gravel in the very brief interval during which the alluvia passes through the dredge. There are as many mechanisms for separating the gold as there are different models of dredge: the ore is scrubbed and larger elements removed by circular screens that vibrate or spin, it is washed to dilute the clay, passed through rectangular metallic or wooden channels, or sluices, with screens of metal, coconut fibre, and sometimes amalgamated copper plates to retain the gold.

Once a deposit had been identified, a company had to be set up, normally with capital from mainland France. These companies had the particularity of being comprised of the person from French Guiana who had discovered the deposit to be mined, the engineer who had studied the deposit and designed his dredge machinery, and the financial backers.

Dredges for French Guiana were built in Europe, mainly in Scottish, Belgian, and Dutch workshops, and then the machines were completely dismantled and sent out as individual parts.

They were transported by steamship from Europe to Cayenne. The equipment was then transported by river as far as the assembly site. Work then started on putting the machinery back together, a process that took several months and started with the building of an assembly workshop, for all of the pieces needed to be bolted or riveted together. The delay between placing an order for the dredge with the manufacturer and commissioning on-site could easily reach two years, and was a genuine adventure in which hard work, tenacity, and ingenuity were needed to overcome the countless difficulties and surprises the Amazonian environment had in store.

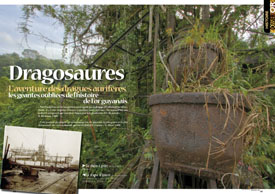

Some of these machines deserve the name “monster dredges” that American historians have given them. They can be forty metres long by ten metres wide with superstructures twelve metres tall and weighing in at 400 tons of metal. Gold dredging with bucket dredges represented a new stage in technological evolution. Once this sort of machinery fell into disuse in French Guiana other methods emerged to replace it, each representing a new leap forward in mining technology. One example of this is draglines which arrived from the USA after the Second World War. The wrecks of these draglines may be found dotted around the creeks, and the most spectacular one in terms of its bulk and machinery is no doubt that brought to the Boulanger placer mine near Cacao in 1956. These automotive machines have a crane and usually caterpillar tracks, and launch their bucket to scoop up the alluvia beneath the water and feed it into a floating scrubbing station. In the 1980s suction dredges made their appearance to mine the alluvia in riverbeds and mechanical shovels took over from draglines for alluvial gold mining.

How many machines were brought to French Guiana? There were certainly fifteen or so machines, but archived documents suggest that over twenty dredges were brought to French Guiana. Data about this activity is still fragmentary even though it relates to the recent past. The existence of some machines is only known from an engraving, or even a single bucket.

In the basin of the Maroni the hulk of the Danica dredge, designed in 1903, may be seen at the confluence of the Sparouine and the Maroni, and the Helena dredge was brought in by the Sparwine company in 1909.

Three dredges are known to have operated in the basin of the Mana: the Orion dredge shipped in by the Mana Syndicate, and two dredges which are still visible at the Elysée placer mine, Suzanne on which Jean Galmot worked (and shipped in by the Société des Mines d’Or de l’Elysée in 1903), and Marguerite which was installed in 1908 by the Compagnie Minière et de Dragage de Guyane.

The only surviving dredge in the basin of the Sinnamary is to be found at Sursaut creek (cf. inset). The dredge Flora sank in 1901 after five months of operation when the level of the water rose in the river, and the dredge Courcibo, which was shipped in by the same company, now lies beneath the waters at the Petit Saut dam.

Lastly, at least six machines were shipped to the basin of the Approuague, initially to the Ipoucin creek (cf. inset) and then in 1926 to the lower Approuague and Mataroni creek by the Compagnie des Mines d’or de la Guyane française, including a novel drilling dredge to prospect the bed of the Approuague.

The bucket dredge endeavour in French Guiana came to an end in the 1930s after a series of failures due to lack of perseverance, bad luck, and frequently the dilapidation of the machinery, lack of money and spare parts, and the difficult operating conditions. In 1952 the Lenormand brothers wrote that “the fate of dredging in French Guiana is now settled”. The technique continued to be used in other places, such as in Surinam where the dredge “Jungle Queen” was taken to Benzdorp in 1963.

What does the future now hold for the old gold dredges of French Guyana?

The fact that this outstanding heritage of the mining industry is so far away should not blind us to how interesting it is, and whilst it is clearly impossible to transport one of these machines today the question of how to best promote them can be addressed in several points. There is a clear need nowadays for a museum to house all the relics of the gold mining and mining industry generally, for the combined effects of the natural environment, time, and numerous incidents of human damage will soon settle the matter once and for all.

English

English Français

Français  Português

Português

![Photo de P-O Jay C’est dans la crique Sursaut, affluent de la crique Tigre aujourd’hui en partie noyée sous les eaux du barrage de Petit Saut, qu’a lieu la première véritable tentative de dragage de l’or en Guyane en 1898. La drague de la Compagnie de dragages aurifères de la Guyane française est conçue par le baron Herre Wyn, capitaine d’infanterie de marine en retraite et directeur de la société.

Cette opération est prévue comme « un programme qui doit révolutionner l’industrie aurifère guyanaise». Après prospection, la teneur est estimée à 5g/m3 et on considère alors que la drague est sur « l’un des plus riches placers de la Guyane et [qu’] elle mourra de vieillesse longtemps avant de l’avoir épuisé. »

La construction est alors réalisée par la société hollandaise Werf Conrad à Haarlem pour un coût de 97.000 F, auxquels s’ajoutent 6.381 F pour le transport de Hollande jusqu’à Sinnamary et 11.683 F de droits de douane, soit 114.297F avant son transport à Sursaut. La drague est embarquée le 15 février à Amsterdam.](http://www.une-saison-en-guyane.com/uploads/galeries/usg5-l-aventure-des-dragues-auriferes/thumbs/thumbs_speranza.jpg)

Télécharger l'article en PDF est réservé aux abonnés Web !

Télécharger l'article en PDF est réservé aux abonnés Web !

Pas de réaction

Pas de réaction Comment!

Comment!

Voyages avec Tooy. Histoire, mémoire, imaginaire des Amériques noires : Editions Vents d’ailleurs, 2010

Voyages avec Tooy. Histoire, mémoire, imaginaire des Amériques noires : Editions Vents d’ailleurs, 2010

Guyane. Produits du terroir et recettes traditionnelles. L’inventaire du patrimoine culinaire de la France : Editions Albin Michel, 1999

Guyane. Produits du terroir et recettes traditionnelles. L’inventaire du patrimoine culinaire de la France : Editions Albin Michel, 1999

Alunawalé, un voyage à travers les milieux naturels de Guyane : Office National des Forêts, 2009

Alunawalé, un voyage à travers les milieux naturels de Guyane : Office National des Forêts, 2009

Augusta Curiel, Fotografe in Suiriname 1904 – 1937 : Libri Misei Surinamensis, 2007

Augusta Curiel, Fotografe in Suiriname 1904 – 1937 : Libri Misei Surinamensis, 2007